It’s been a week of eclectic heavy weights at mono motorcycles this week.

It’s been a week of heavy weights at mono motorcycles this week. A Honda VFR, BMW K1300’s, Aprilia RSV4 RR & to complete the line up; a Polaris Quadzilla buggy with a CBR600 engine! Eclectic is the name of the game at mono motorcycles.

We began our week with the immaculate Honda VFR. The VFR has been through 3 regulator rectifiers over the past few years & when the most recent one failed, it blew the rev counter at the same time. Following an extensive conversation with our customer, it was agreed that to ensure the power was able to be regulated correctly going forward, that the stator & reg rec would be replaced at the same time.

Our customer procured the parts himself, which also included a new battery & essential gaskets for when the VFR was rebuilt.

When Daniel removed the stator, it did have some tell tale signs of excessive heat, as the winding’s around one side of the stator were a deep caramel colour.

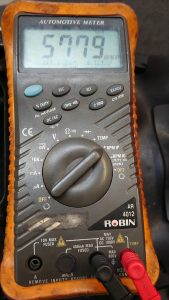

Once the reg rec was fitted & Daniel was able to start the VFR, he then set about diagnosing the issue with the rev counter.

Under test, he was able to get a signal from the dash wiring. Then, through chasing the signals through the rest of the wiring,Daniel isolated the issue to the motor inside the rev counter. The motor inside had burnt out in the surge from the reg rectifier failing.

We welcomed a Suzuki Bandit to the workshop on Tuesday for a carburettor rebuild & running issues.

Our customer was assured that having no former knowledge of the Bandit, we could not guarantee that a carb rebuild would cure the running issues 100%. As is the nature of carb builds, unless all the internal parts are of good quality, in a very good state of repair or new; no carb rebuild can ever be 100% assured.

Once Daniel had taken the tank off, he found an initial problem which wouldn’t have helped the running issues. One of the HT leads was badly damaged & partly melted. This was duly repaired.

The carburettor bodies were removed from the Bandit. However, whoever had completed works on them previously, had not necessarily been very considerate to the delicate nature of their construction. Daniel found that not only were several of the jet screws rounded off, but the air screw had been completely annihilated with a screwdriver. We did a very quick search online for another set of carbs & found a 2nd hand set in the USA at £350.00 & £2k for a new set in the UK.

Wanting to go back to our customer with a solution, Daniel suddenly remembered we had a second hand set of Bandit carbs from previous works. When they were unearthed, they were in better condition to the ones we had just taken off. Once stripped, ultrasonically cleaned & rebuilt; they were refitted to the Bandit.

Once the fuel had been replaced, the engine fired up. Once the carbs had been replaced & balanced, the motor revved well, something it had not done so before.

It was during the road test afterwards, that Daniel noted something didn’t feel right on acceleration. Upon further investigation, he found that the fuel tap which had been fitted, was the wrong bore for the Bandit. The hose should have been 10mm & the one fitted was 6mm. This meant under load, the Bandit could be at risk of running out of fuel.

Having advised our customer of the needs for the Bandit, which included replacing the tap & hose & that the Bandit could do with a good service; she will be returning to us again for the continued works to be undertaken.

Daniel was offered a test ride on one of customers Aprilia RSV4 RR this week & of course he couldn’t refuse! In Daniel’s words “that is the fastest road bike I have ever ridden” through a grin!

The first of two BMW K1300’s joined us on Wednesday for an interim service & MOT.

Part of the service for the K1300R was to undertake a full diagnostic sweep & turn the service light out. Reaping the benefits of the TEXA diagnostic capabilities at mono motorcycles.

The second K1300, the BMW K1300S, joined us on Thursday for servicing & wiring upgrades.

We end our week with one of our more unusual projects.

Daniel was approached a couple of months ago, by a man looking to have a reverse gear fitted to a buggy. The Polaris Quadzilla buggy has had a CBR600 engine fitted to it!

The customer had had a bespoke system built for the buggy, which was a starter motor & a sprocket which was made to allow the engine to have a reverse gear. However, it was only on the initial road test (thankfully around the farm) that Daniel discovered the brakes were not working, at all!

Therefore, our first priority was to make the buggy safe & set about fixing the brakes.

Once these were underway, Daniel set about fabricating & mounting a bracket to hold the new starter motor. Having held the components up against each other, he noted that the reverse gear sprocket was too small & that the starter motor would hit the chain. He then fabricated & welded an additional section to the set up, using a gear cog off a ZZR. Once wired up & installed, the motor worked first time & the buggy now has a reverse gear. This is an ongoing project which needs some TLC.

We have decided to run some basic motorcycle safety & basic motorcycle maintenance workshops, following requests from some of our customers. They are not designed to teach how to change oil, brakes, tyres etc, but are designed to give novices & those who lack confidence in their own motorcycle knowledge, the basics of what to monitor & look for in general motorcycle maintenance.

Our first breakfast club of 2019 is just around the corner, on Sunday 28th April. We look forward to welcoming everyone to these very popular events.

As always, for all your motorcycling needs, contact Daniel or Katy on T: 01243 576212 / 07899 654446 or through our contact page.